Catenary Antifreeze Lubricator

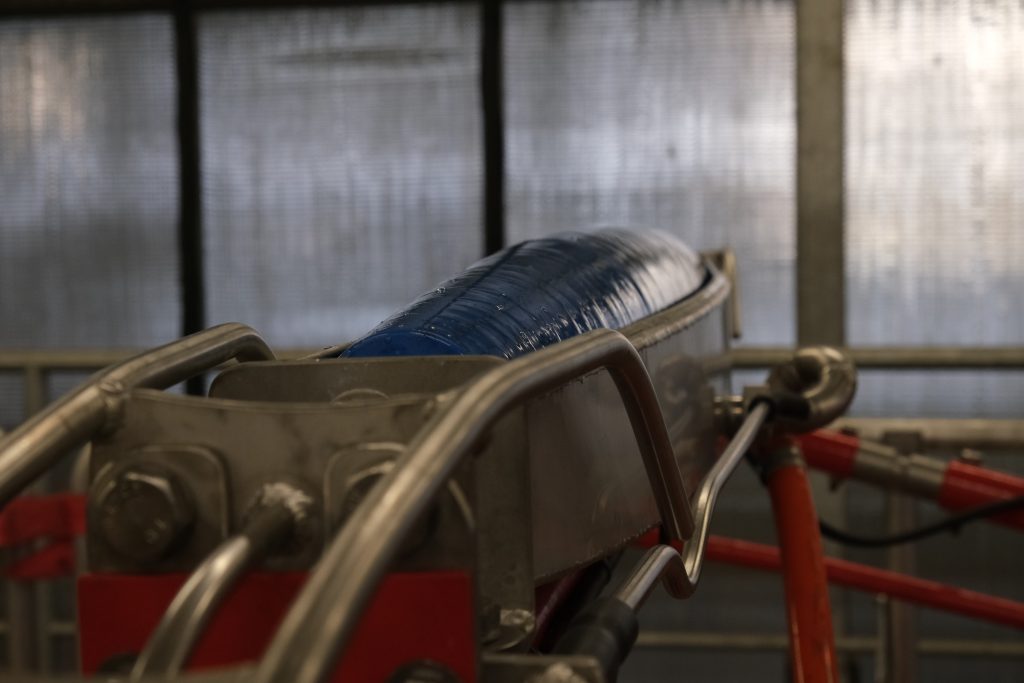

The catenary antifreze lubricator (CAL) is a mechanical device for applying antifreeze fluids to a catenary wire from a moving rail vehicle. The unit has to be mounted on a pantograph.

The mechanical catenary antifreeze lubricator is a development project by Simchen’s Mechanical Design. Conventional anti-ice devices, such as felt roller systems, have shown that chemical catenary ice protection is useful in the interim period with alternating temperatures about and below 0°C / 32°F. At Dresden’s tramway, the sometimes fragile technology often challenged us in operation and maintenance.

The project was launched with the aim of developing a simple, robust mechanism that applies antifreeze to the overhead contact line in a suitable quality, requires no special care and performs trustworthy in the harsh conditions in the daily business of a tramway.

Patented working principle

The catenary antifreeze lubricator works according to a slide-and-roll process. The centerpiece is the so-called conveyor roller. Its bottom dips into a reservoir filled with anti-ice fluid. The upper edge of the roller touches the catenary wire. Instead of rolling along, it slides along it. A low-speed servo motor turns the roller slowly, so that just enough antifreeze is conveyed to the upper edge of the unit.

An external level-retaining manifold maintains the correct fill level of the tub and keeps the backflow clean from environmental dirt and graphite wear.

Gentle on the catenary

The CAL does not require a high contact pressure. It is designed so that simply touching the contact wire ensures a successfull operation. The lower the friction hysteresis in the pantograph, the lower the basic contact pressure can be adjusted.

Nimble

The system is not affected by high travel speeds. There is no imbalance or centrifugal force known from high-speed rollers. Thanks to the contact method, the system resists wind.

Eco-friendly and cost-efficient at once

Efficiency means how much of the filled-in antifreeze actually reaches the catenary wire. The mechanical contacting principle avoids the spray losses that occur with nozzles. The slide-and-roll process has no losses of fluid that is flung away by any centrifugal force of a fast rotating felt-roller and because of the external overflow system even the backflow can be reused!

Takes on any obstacle

The CAL can be manufactured in a geometry that corresponds to a standard contact strip. The low contact pressure also prevents the catenary from being raised to an unusually high level, so that collisions with positioners or crossing contact wires are fortunately not to be feared.

Safe

The CAL has no heavy and fast-rotating components which, due to their imbalance, would cause vibrations in the vehicle or catenary.

Reliable. Even at 3 AM on a Monday morning.

The CAL has a sensorless design. It only needs a single control signal if the vehicle is moving. If it should fail or does not receive a control signal from the vehicle, it will not damage the catenary.

Versatile

The CAL makes no special demands on the homogeneity and viscosity of the antifreeze. By adjusting parameters likethe circumferential speed of the roller or the fill level height in the reservoir, the device can be adapted to different anti-icing agents, layer thicknesses and general operating conditions. The plain surfaces in the device open the door to highly specialized and environmentally friendly antifreeze chemicals and non-Newtonian fluids.

Technical data

| Overall width: | e.g. 1744 ±10 mm |

| Applicator width: | 1000 mm |

| Weight: | approx. 18 kg |

| Contact pressure: | 0.5…2 kg |

| Power supply: | 9…36 V |

| Power consumption: | <5 W |

| Isolation: | 2.5 kV (basic configuration) |